'TurBo' is a Takeuchi TB36 hydraulic excavator and is one of the first in the country manufactured in C.1988.

Cost new: £14000

Engine: 3 Cylinder turbocharged Yanmar

A job has arisen that requires the use of a 3 tonne hydraulic excavator. We have felt this is the perfect opportunity to restore this machine after nearly 6 years sitting idle.

The aim of the restoration over the next few months is to replace all pins, bushes, tracks, sprockets, idlers and even nuts and bolts!

This blog is to show the progression of the restoration plus it will aid in the re-build!

This blog is to show the progression of the restoration plus it will aid in the re-build!

|

A day of getting covered in diesel and hydraulic oil!

|

The tanks all cleaned out ready for shot blasting

The slew bearing also needs replacing, Managed to find one in Japan.....the last one available!

Tracks

This is proving to be a bit of a problem. We don't seem to be able to find 300mm steel tracks. Let's just hope someone somewhere has a pair

|

The new slew bearing! Better keep that safe as we wont be needing that for a day or two!

A broken sledge hammer handle and a blow to the head later we got the better of it!

The engine is sound and had an overhaul less than a thousand hours ago, no need to do anything here.

I think that's as far as we dare to go with the body, All remaining parts will be suitably masked up ready for shot blasting and painting.

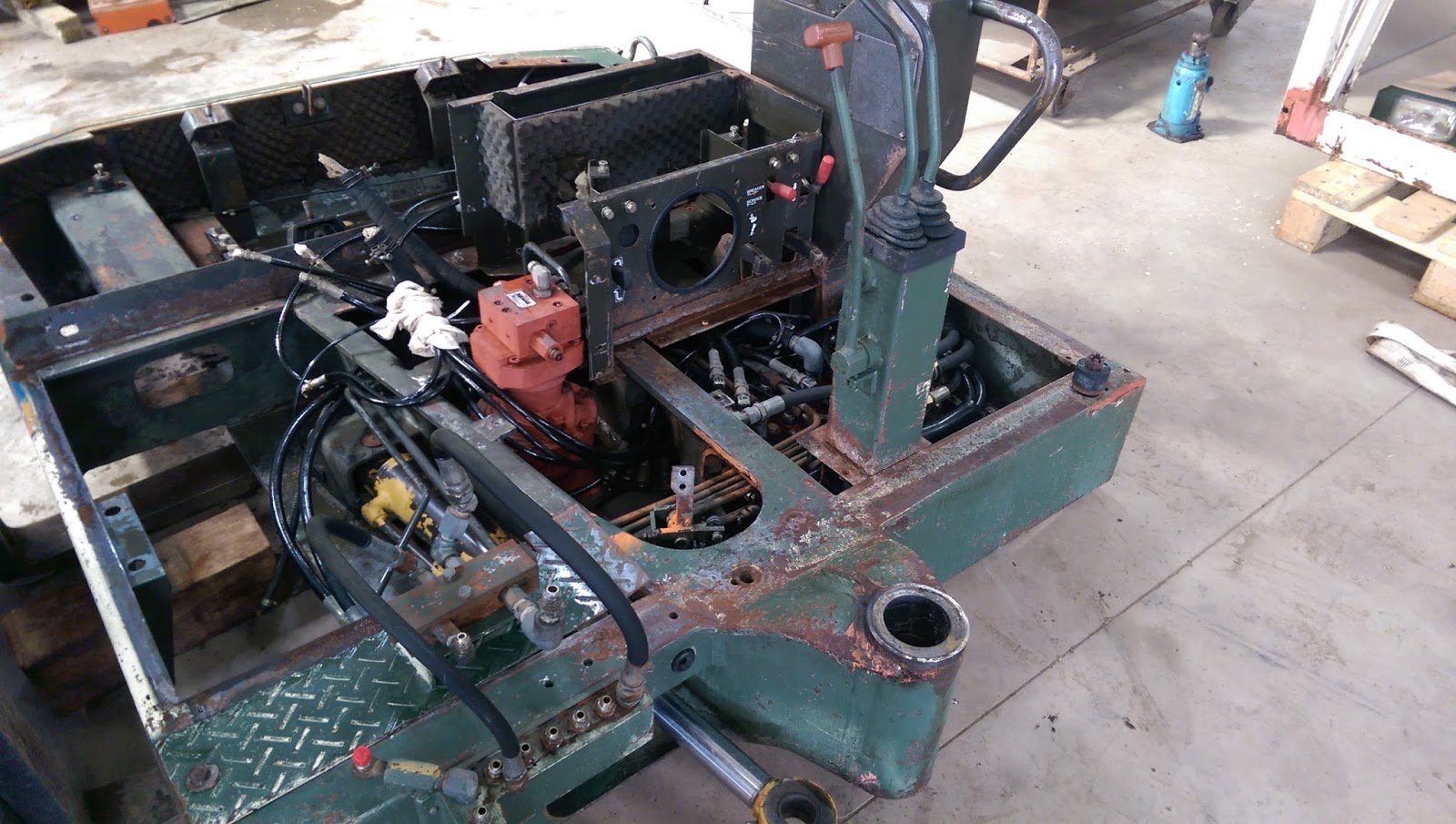

Track motors and distributor valve on today's agenda!

I hope I can remember how it all goes back together!

I thought the king post was a hard job, these hubs just didn't want to budge!

Now on to the cab!

After having had a few smacks and seen enough rain to float the arc, dents and rust are the cabs worst enemy. But in all fairness it's not actually that bad.

Out with the grinder and welder!

All painted parts are to be blasted to remove paint and rust.

Gary Cooper from Moorland Blast Cleaning is the man for the job. Gary uses a non aggressive medium in the form of recycled crushed glass. This is just enough to remove paint and rust without damaging or distorting any of the steel work.

Straight after each blasting session enough

time is made so all the blasted components

can be painted with a 2 pack primer to

ensure no mill rust will occur.

Now for the Paint!

The shot blasting revealed some previously filled dents and marks so they have had to be re filled and flattened back. The worst parts were the cab and engine cover. After many hours filling and sanding, the workshop somewhat resembled the north pole with a thick layer of filler dust.

Filler primer is the next step on all high visibility parts to give a smooth flawless finish.

[i'm beginning to sound like I know what i'm doing!]

The undercarriage will get a basic grey primer before its dark green top coat

remember where

all the bits go!

Woohoo! Paint has arrived!

Seems to be mixed reactions with the satin green, but it's as close to the original color as I could find.

Makeshift spray booth!

Starting to come together now..... albeit slowly!

New Pipe swaging machine has arrived allowing us to carry out our own Hydraulic repairs, plus I could finally get the distributor valve in!

Tracks! all the way from Italy....Thanks Berco

....and we're getting there!

Makeshift spray booth!

Starting to come together now..... albeit slowly!

New Pipe swaging machine has arrived allowing us to carry out our own Hydraulic repairs, plus I could finally get the distributor valve in!

Tracks! all the way from Italy....Thanks Berco

And it's FINISHED!

Its been a few months but finally It's out in the yard with the rest of them, How times have changed!